-

Pressure

- Electronic pressure switches / Pressure transmitters

- Differential Pressure Switches

- Mechanical Pressure Switches

- ATEX Mechanical Pressure Switches

- Vacuum switches

- ATEX vacuum switches

- Pressure customized products

- Pressure catalogue

- Pressure Configurator

-

Temperature

-

Level

- Adjustable Level Switch

- Standard Single- or Two-Point Level Switches

- Standard 3- or 4-Point Level Switches

- Low Cost Level Switches

- Level Switches set to be completed

- Intrinsically Safe ATEX Level Switches

- ATEX Explosion-Proof Level Switches

- Level sensors

- ATEX level sensors

- Level catalogue

- Level Configurator

-

Flow

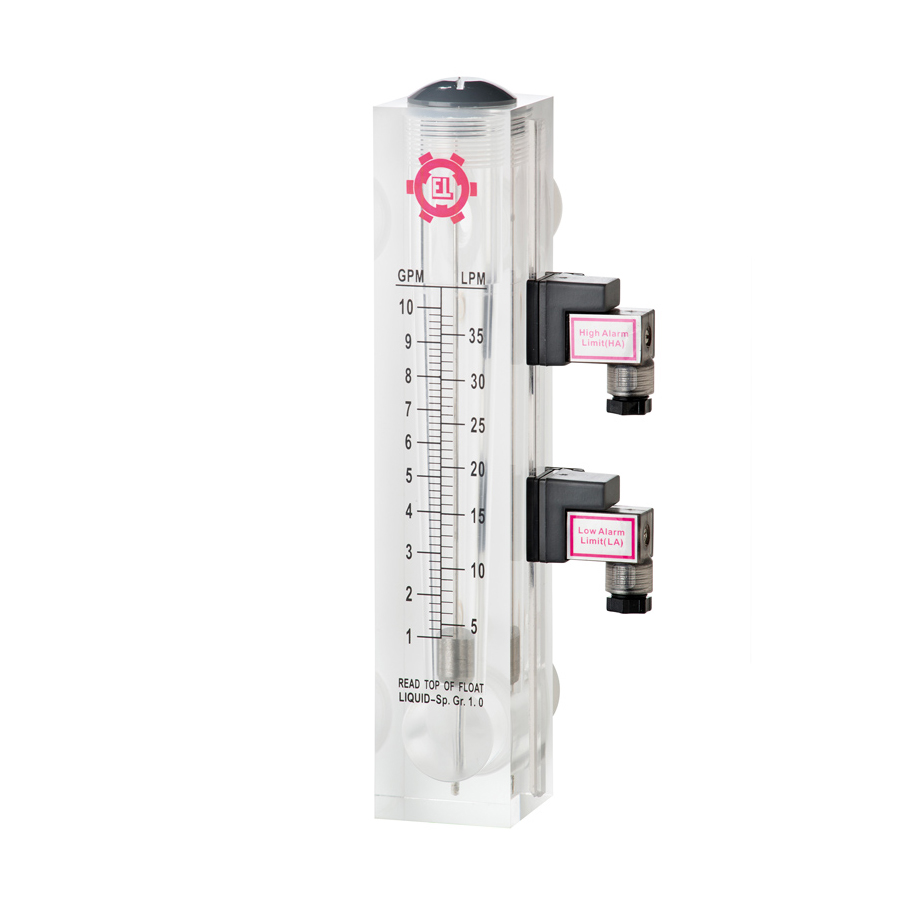

Variable area Flow meters

Flow meters are instruments designed to measure the volumetric flow rate of a gas or liquid.

The Advantages of Elettrotec Industrial Flow Meters

Elettrotec industrial flow meters have been a benchmark in various international markets for over 40 years.

Maximum operational safety

Selection of high-quality materials such as stainless steel, ensuring excellent compatibility with most industrial fluids

Complete absence of friction in moving parts

Adjustment of the set point across the entire scale

Robustness due to the particular compact construction

Insensitivity to fluid pressure

Sealing gaskets made of nitrile rubber, FKM (VITON®), or EPDM.

Are you looking for industrial flow meters for your company in Milan or the surrounding area?

Other good reasons to choose Elettrotec solutions (and grow your business):

EXPERIENCE: We were the first, in 1977, to develop the potential of fluid control devices for industrial production.

CONSULTING: In addition to simply supplying products, we offer a consulting service, supporting the customer step by step even after the sale is finalized.

SUSTAINABILITY: We have been committed to the environmental sustainability of our supply chain since the beginning of our company’s history.

**For more information or to request a quote for our industrial flow meters, you can contact our sales.

What is the purpose of a flow meter?

Flow meters and flow switches are typically used to monitor the passage of a fluid or gas in a circuit, providing a simple flow rate indication or, in versions with a contact, transmitting a remote alarm signal to a control panel if a variation in flow intensity is detected.

When is a flow meter used?

A flow meter is used in water, oil, and gas loading and unloading systems, as well as in cooling circuits, heat pumps, heaters, welders, transformers, heat exchangers, compressors, and in the chemical, pharmaceutical, and food industries, etc.

How does a flow meter work?

Adjustable visual and electric flow switches consist of a body, two connection flanges, a shutter with a permanent magnet, a Pyrex glass tube with a graduated scale, a shutter guide tube with variable passage sections, sealing gaskets, a slider with magnetic contacts, and a connector for electrical connection.

The fluid or gas flow, entering from the bottom upwards in the vertically mounted flow switch, pushes the shutter upwards along the tube with a variable passage section, positioning it in the range indicated by the graduated scale on the Pyrex glass tube. At the upper end, marked in red, the instantaneous flow rate present in the circuit can be read.

The shutter, immersed in the fluid stream, is free to move without mechanical friction and, thanks to the magnetic field generated by the magnet housed inside it, activates the alarm electrical contact. Using the mobile slider with a reference index, the contact can be positioned at the flow rate to be monitored, marked on the side label. The movement of the slider must be locked using the screw located under the connector.

Types of Flow Meters

There are several other types of flow meters: visual flow meters, electric flow meters, and visual/electric flow meters.

In which fields are flow meters used?

The fields of application for flow meters are diverse. In the industrial sector, they are present in chemical plants, pharmaceutical plants, energy production facilities, etc.

TFM…V – Variable area flow meters

TFM2E… – Variable area flow meters with 2 adjustable electrical contacts

FMP…V – Variable Area Flow Meters (panel type)

FMP…VR – Variable area flow meters (panel type flow meters with regulating valve)

FMP2E – Variable area flow meters (panel type) with 2 adjustable contacts

FMX…VR – Variable area oxygen flow meters (panel type flow meters with regulating valve)